Our End-To-End Service Has You Covered From Concept To Car

Each project we touch is unique. But whether we’re co-developing cubing solutions with OEMs or delivering checking fixtures for a tier 1 supplier, our customers have a clear view of where their project stands in our defined workflow.

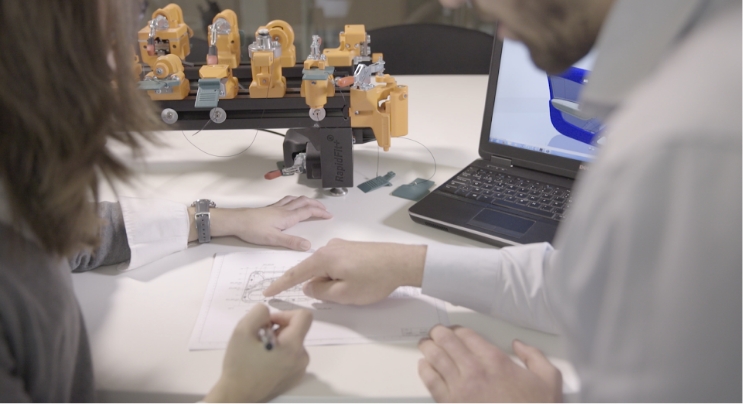

1. Requirement definition

An application engineer from our team gets in touch with you to scope the project and understand your goals. At this point, we’ll send you a quote, an estimated lead time, and a clear definition of the project scope.

2. Design process

We identify the most effective combination of technologies to design a custom tool that meets your specific needs. Say: modular fixtures created with 3D-printed connection that enable accurate, adjustable, and repeatable measurements.

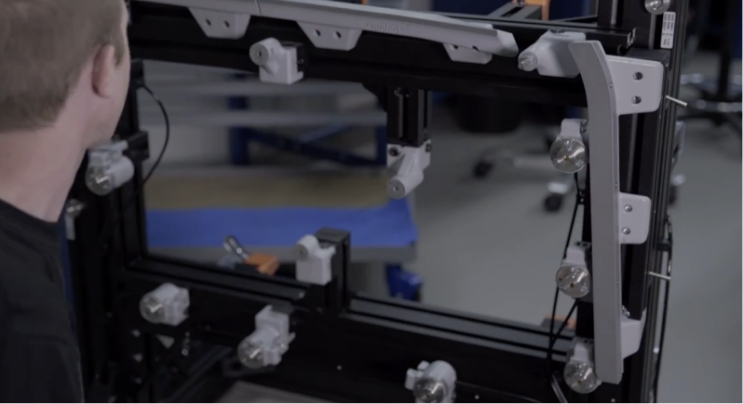

3. Production

Using a combination of innovative technologies and materials, we manufacture your tools. Assembly takes place in a temperature-controlled environment, overseen by a highly skilled and experienced team. Post-production steps, including 5-axis CNC milling, are also covered in-house.

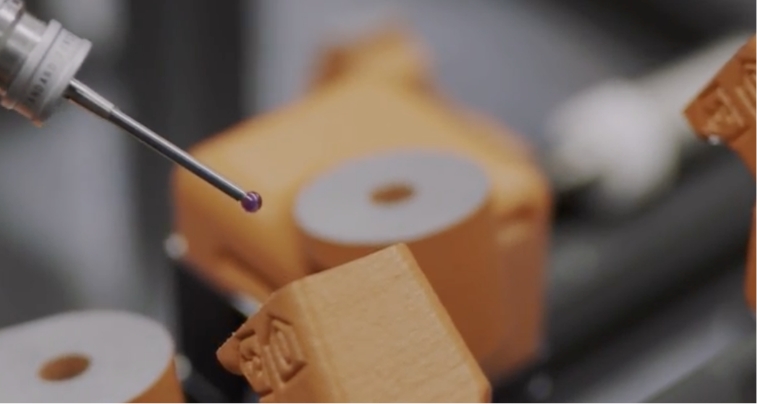

4. Calibration

We calibrate your tools in a temperature-controlled lab environment with top-of-the-line CMMs (coordinate measure machines). Our digitized process ensures high-quality, accurate results delivered faster than traditional methods.

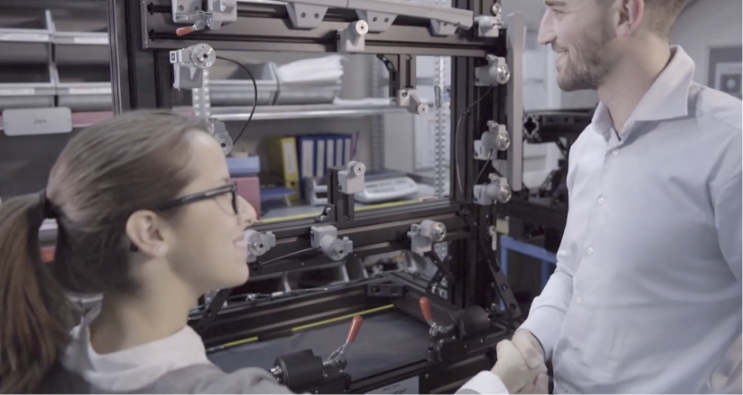

5. Buy-off

Whether we’re at your location, our facilities, or communicating digitally, we’ll inspect the final result together with you to ensure that our solution meets your expectations. We optimize the timing of the process to maintain short lead times.

Validating Automotive Tools Digitally

We understand the need to cut back on travel, whether for the safety of your and our teams during the current pandemic or to reduce financial and environmental costs once travel is permitted again. That’s why we have a digital validation process in place. We’ll provide first-person views, detailed calibration reports, and live demonstrations, so you won’t miss out on any details you’d get in person.