Can you teach old robots new tricks? RapidFit’s end-of-arm gripping solution proves you can. Discover how the ‘Big Gripper’ reduces the payload of robotic arms, saves costs, increases accuracy, and allows factories to upskill their machinery.

Lightweighting is not a new concept in manufacturing, though it is often applied to parts and materials. RapidFit chose to take it one step further by looking instead at what holds these parts in place. Digitalization has transformed factories around the world by introducing powerful robotics into their workflows to lift, hold, or otherwise maneuver parts. The larger the part in question, the larger, more powerful, and ultimately more expensive the machine required to move it.

It’s a pretty standard correlation — but there is an alternative. Whether you need it for assembly, gluing, welding, or any other application, RapidFit can replace your standard jigs with a custom-made, lightweight 3D-printed frame that greatly reduces the total payload robots need to lift. This allows manufacturers to repurpose smaller, less powerful, and considerably more affordable models rather than investing in something stronger. The result? Big savings.

“The price to produce the tools needs to be competitive, and I believe it is. But the biggest advantage — and it’s a huge advantage — is the reduction in the payloads of the robotic arms,” explains Koen Briers, Sales Manager at RapidFit. “You can use smaller robots, and by using smaller robots with less power or capacity, you will save a lot of money.”

Here, modularity also comes into play. RapidFit can ensure the frames are adjustable and create different setups as required. Automotive manufacturers, for example, could request a frame that lets them work on two types of roofs for the same vehicle, allowing them to use one gripper instead of two. This would not only save them money but time and space, as well.

Lightweight, strong, and accurate

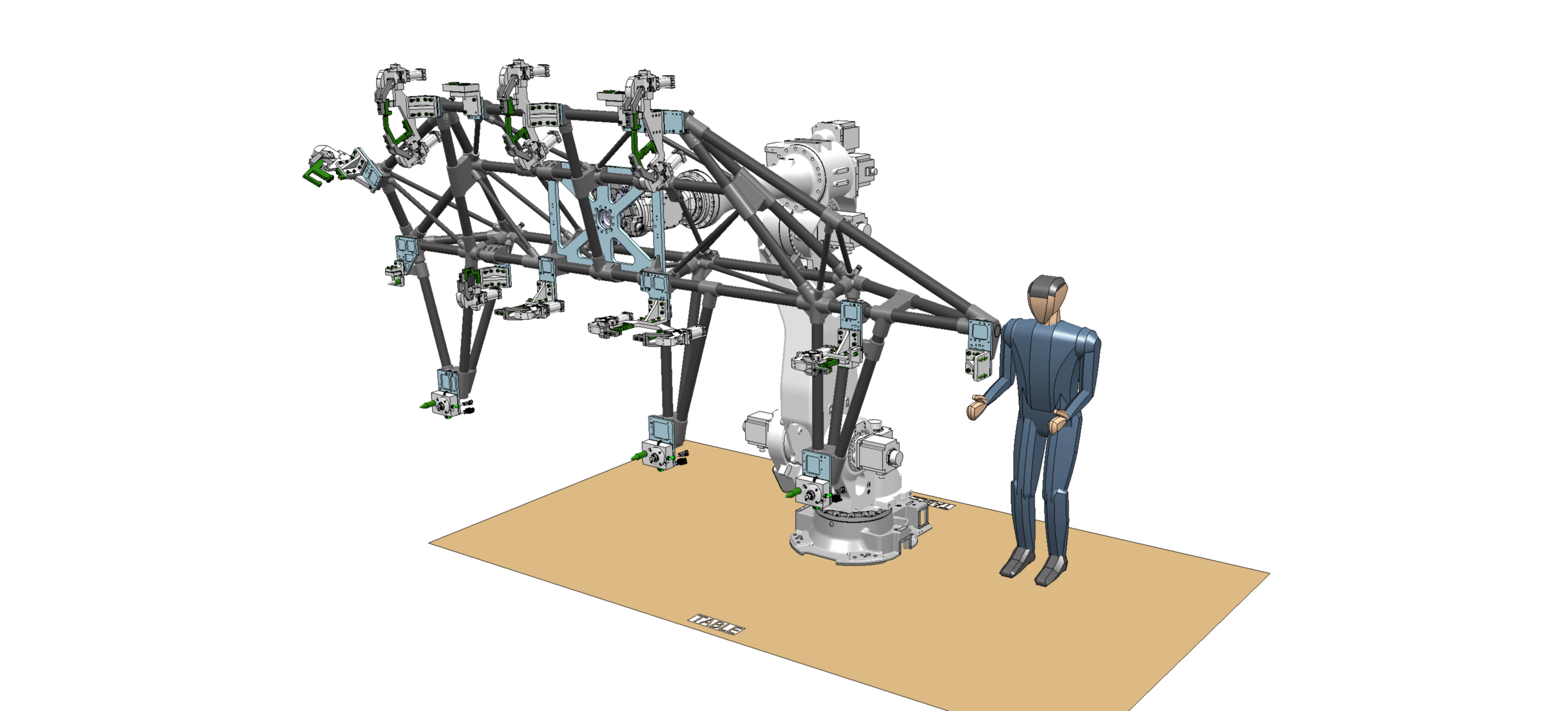

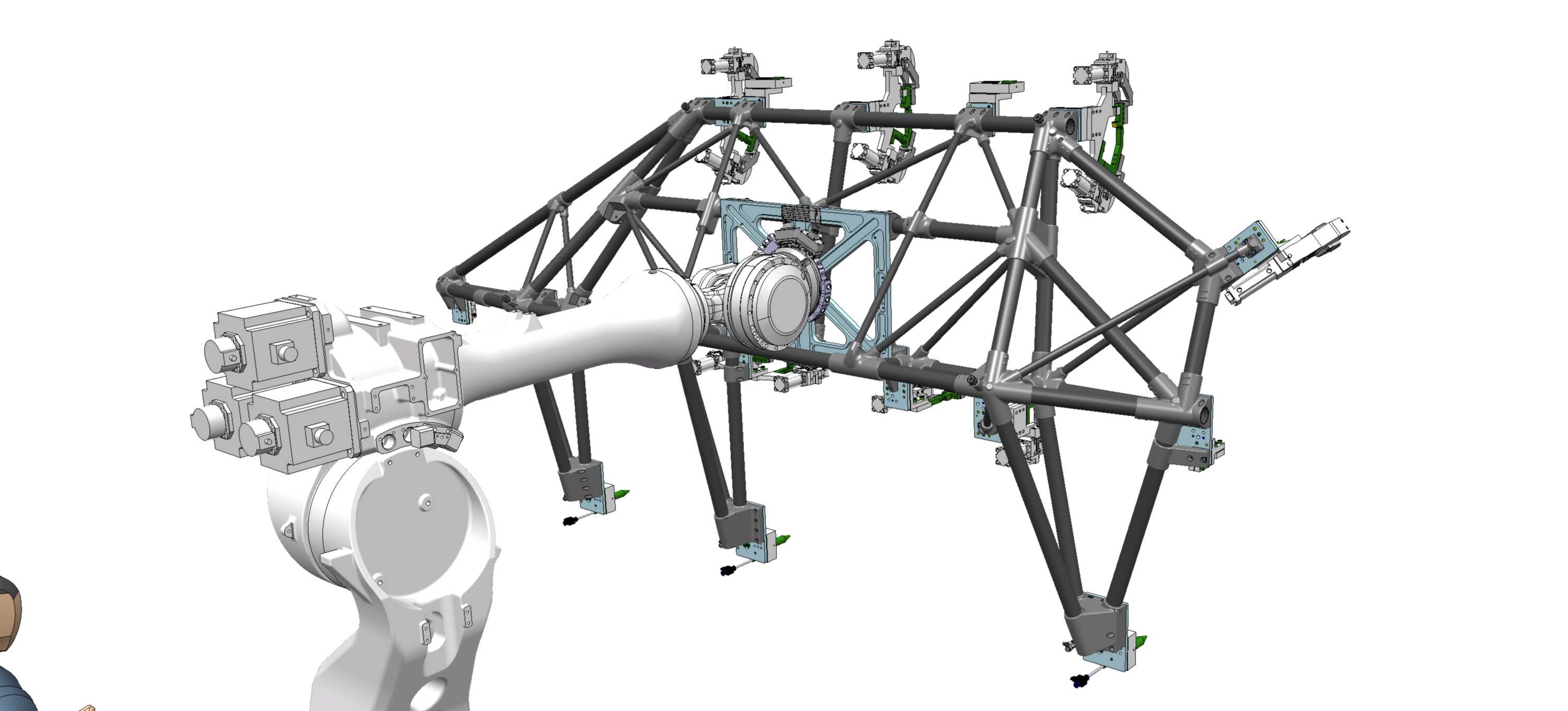

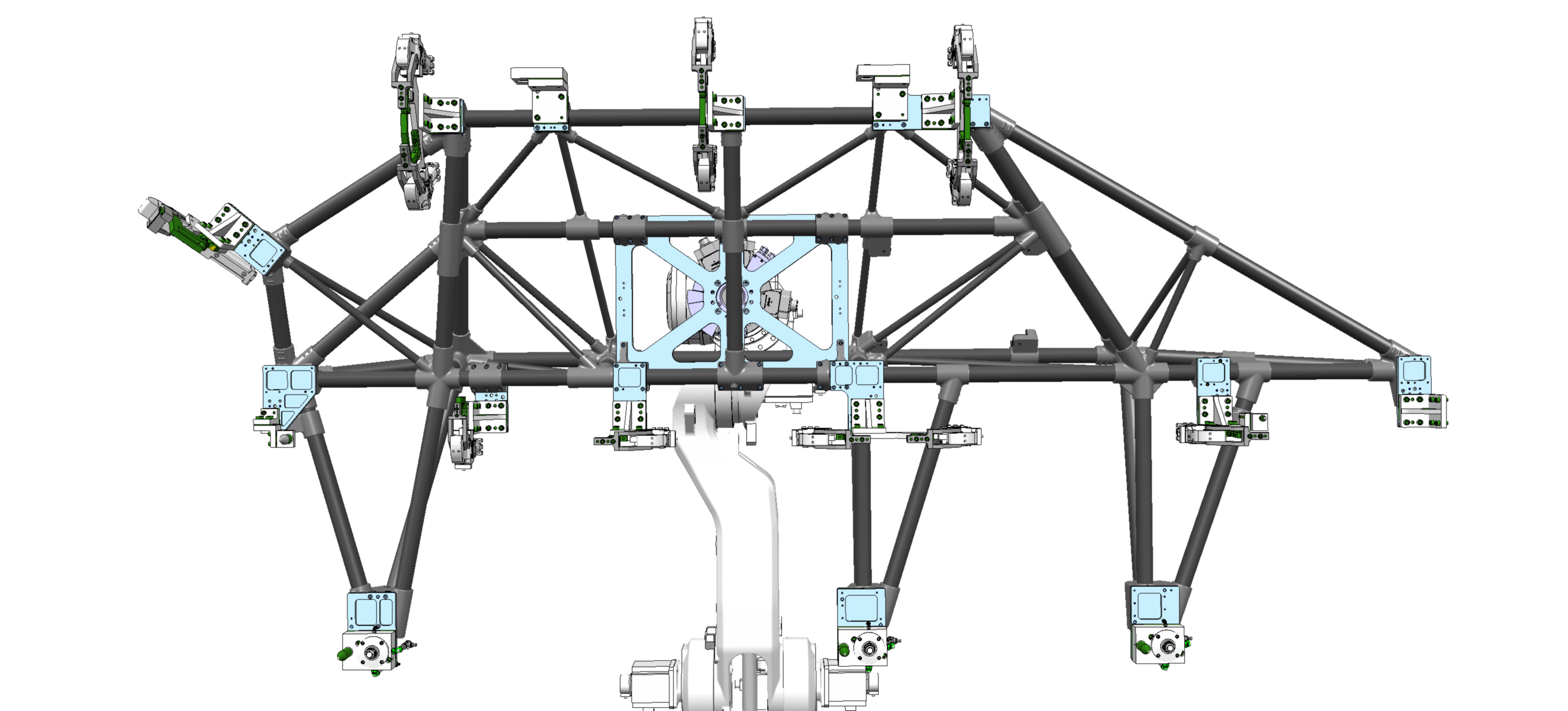

The first iteration of this new jig, known fondly as the ‘Big Gripper,’ was designed to do precisely what the name suggests: hold on tight to large parts. When working with something of this scale, strength remains an important factor. Using carbon rods, 3D-printed connectors, and a patented gluing system ensures that the jig boasts optimal strength and stiffness in all directions, so the part is secure while the manufacturing team works on it.

Making 3D printing a core part of the production process is key. Beyond creating the necessary connectors, its unparalleled design freedom allows RapidFit to get creative when searching for solutions. The team can eliminate any design limitations of the grippers themselves and work around the function of the robotic arms they’re made to fit.

This design process is also highly accurate. The standards to which the grippers are built allow them to reach low-standard assemblies that would not be possible with welded frames or concepts.

But above all, it’s the weight-saving capabilities Koen mentioned that are the most impressive benefit. The first design, shown above, came in at around four meters in length yet weighed only 30 kg — considerably lighter than traditional tools. A later version, prepared for a customer specializing in prototyping, weighed 62 kg. RapidFit’s calculations suggest that it will help reduce the total weight the robot needs to carry from 280 kg to around 130 kg — an incredible reduction of approximately 150 kg. Not bad for a tool that has to hold half a car’s worth of aluminum.

Naturally, it’s not one-size-fits-all here. The customization aspect means RapidFit can produce grippers of all shapes, sizes, and functions — you could create your own ‘Little Gripper’ if you see fit. You don’t need to be lifting vehicles to take advantage of this new solution.

What’s on the jig?

The main components are all produced by the RapidFit team. Alongside the carbon rods and 3D-printed sockets, the aluminum connecting plate is the most important feature. It’s here that the robotic arm attaches to the jig, with decisions regarding its placement made alongside the customer during the design process.

“In the Big Gripper’s case, the design process was very specific,” says Koen. “We received the CAD data of the part itself and a sketch of the jig where they defined the important areas. We made a quote and, together with the customer, evaluated where the attachments and any specific equipment needed to go. We take that input into account when we design the jig.”

In this example, the customer placed the clamps, magnets, electrical wiring, and any other equipment needed to grip the part themselves, but it is also a service that RapidFit is happy to provide. Either way, knowing their location ahead of time is important due to the programming each robot requires.

Where can the jigs be used — and how can you get one?

“Wherever there are robots, our solution can be used,” says Koen. So, how can you get hold of one? As each jig is unique and made to order, every project begins with a conversation and a little information.

“What part do you want to move? What functionalities do you need? Should we also design and build the electronics or pneumatics? What robot are you using? Tell us about how it connects to the jig and any weight restrictions. After that, we can start working.”

The RapidFit team has the capabilities to complete these requests quickly. The first project took only eight weeks from start to finish, with Koen confident they could deliver in as little as six. That’s a big requirement for industries like automotive, where deadlines are tight.

Of course, the sooner you start, the sooner you’ll receive it. So, if you’d like to learn how these end-of-arm solutions can upskill your own robots — and save you a lot of money in the process — get in touch with the team today.